Are you operating a vacuum coatings system that is mechanically sound, but the controls and electronics are not up to date anymore?

Do you have user interfaces that are from the last century – and lack features like data logging and visualization?

Are your PLCs and Drives obsolete and every failure puts you at the brink of extended downtimes?

Would you like to bring your systems “up to date” but have a tight budget?

If you answer “yes” to any of the above questions we can offer a solution. Specializing in Retrofits, Upgrades and Refurbishment we have ready solutions for you. We have provided numerous “turn key” upgrades to many systems around the world, saving owners and operators 100’s of thousands in extending the operational life of the vacuum system. Operational stability and often process and productivity improvements are the major benefits from retrofits and upgrades.

We provide:

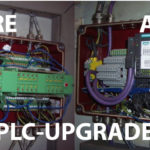

PLC upgrades and replacements

Modern User Interfaces and Visualization Systems

Mechanical Upgrades for Pumps, Motors, Bearings and other mechanical components

Wirefeed Upgrades for older Metallizing Machines providing indiviual wire feed controls

System retrofits for additional capabilities such as plasma surface treatment and sputter capabilities.